Contact us at info@tycosealing.com to solve all your queries and get clarification

Our Products

Explore our comprehensive selection of top-tier industrial gaskets

Our Products

Explore our comprehensive selection of top-tier industrial gaskets

Tyco Sealing Products

Tyco Sealing Products

Metallic Gaskets

Metallic Ring type Joint gaskets are used in high pressure applications for exploration and production in Oil and Gas Industry.

A gasket is used to create and retain a static seal between two flanges which connect a series of mechanical components while containing a wide variety of fluids (liquids and/or gases). These static seals aim to provide a complete physical barrier against the fluid contained within and block any potential leak paths through gasket material or between surfaces of flange and gasket, while still being capable of being disassembled and reassembled.

Ring Type Joint Gaskets (RTJ Gaskets) Ring Type Joint (RTJ) gaskets are vital components in ensuring secure, leak-free connections in high-pressure and high-temperature environments, common in industries like oil and gas, petrochemical, chemical processing, and power generation. These precision-machined metallic gaskets meet industry standards API 6A, API 17D, and ASME B16.20 and feature a distinctive oval or octagonal design, fitting precisely into grooved flange chambers, creating a reliable metal-to-metal seal when flanges are tightened. RTJ gaskets are available in various materials, including carbon steel, stainless steel, and specialized alloys such as Monel and Inconel, ensuring adaptability to diverse industrial needs

A standout feature of RTJ gaskets is their unique ability to deform under compression, allowing them to tightly conform to flange face irregularities, resulting in dependable and leak-free seals, even in the harshest operating conditions. Their excellence in extreme pressure and temperature environments makes them highly valued. Their adaptability in terms of size and material options further adds to their versatility and widespread use in critical applications, especially in industries where maintaining dependable seals between flange connections is of utmost importance, ensuring safety and reliability. RTJ gaskets are a trusted choice for professionals working in demanding and high-stakes environments.

Selecting the right material for Ring Type Joint (RTJ) gaskets is crucial for effective sealing in various applications.

Gasket material selection hinges on two key factors: compatibility with the fluid being sealed and the flange's hardness. Ideally, the gasket material should be softer than the flange material to allow for proper gasket deformation without harming the flange surface.

| Material | UNS Number | Max. Brinell Hardness | Max. Rockwell Hardness | Description |

|---|---|---|---|---|

| Soft Iron | 90 | 56 | D | |

| Low Carbon Steel | 120 | 68 | S | |

| 4-6% Chrome 1/2% Moly | K42544 | 130 | 75 | F5 |

| Type 304 Stainless Steel | S30400 | 160 | 83 | S304 |

| Type 316 Stainless Steel | S31600 | 160 | 83 | S316 |

| Type 347 Stainless Steel | S34700 | 160 | 83 | S347 |

| Type 410 Stainless Steel | S41000 | 170 | 86 | S410 |

| Titanium Grade 2 | R50400 | 215 | 94 | |

| Alloy 600 | N06600 | 200 | 92 | |

| Alloy 625 | N06625 | 200 | 92 | |

| Alloy 800 | N08800 | 200 | 92 | |

| Alloy 825 | N08825 | 160 | 92 | |

| Hastelloy | N10001 | 200 | ||

| Alloy C276 | N10276 | 200 | 92 | |

| SMO 254 | S32154 | 180 | 89 | |

| Zeron 100 | 200 | |||

| Super Duplex | S31803 | 200 | 92 |

Benefits of Using RTJ Gaskets Ring Type Joint Gaskets offer several advantages over other types of gaskets, making them the preferred choice for high-pressure and high-temperature applications. Some of the key benefits include:

R-Oval Gaskets

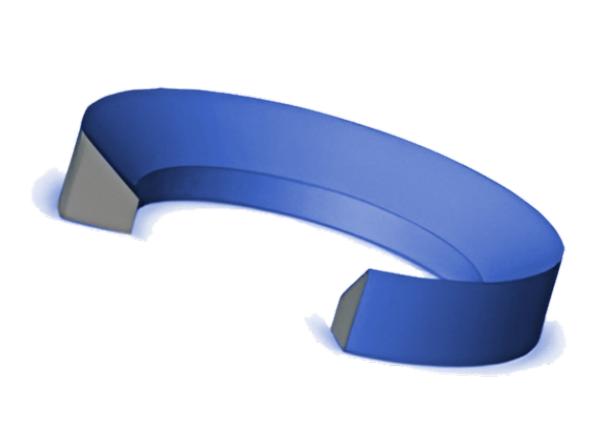

R-Oval type gaskets, abbreviated as OVL, are designed for sealing flange grooves with a flat bottom v-groove or a bottom radius groove. They offer reliable performance in pressures up to 10,000 PSI, although the octagonal type boasts a higher sealing coefficient and is generally preferred.

R-Octogonal Gaskets

R-Octagonal gaskets are essential for high-pressure applications, with a superior sealing coefficient compared to oval counterparts. Designed to match the flange groove's pitch diameter, they excel in flat-bottom v-grooves and remain the preferred choice for effective sealing at pressures up to 10,000 PSI.

R-Octogonal Gaskets

R-Octagonal gaskets are essential for high-pressure applications, with a superior sealing coefficient compared to oval counterparts. Designed to match the flange groove's pitch diameter, they excel in flat-bottom v-grooves and remain the preferred choice for effective sealing at pressures up to 10,000 PSI.

RX Gaskets

The RX type ring gasket is a high-pressure metallic seal used in industries like oil and gas, petrochemical, and chemical processing, particularly in API 6A flanges for challenging & extreme outrageous conditions. We offer wide range of Type Rx Gaskets ranging from RX20 to RX215.

BX Gaskets

BX gaskets, compatible with R Type Oval and Octagonal rings for API 6BX flanges, withstand pressures up to 20,000 PSI. A pressure balance hole is incorporated in BX gaskets which ensures the pressure equalisation. Our range includes BX150 to BX303 gaskets for various applications.

BX Gaskets

BX gaskets, compatible with R Type Oval and Octagonal rings for API 6BX flanges, withstand pressures up to 20,000 PSI. A pressure balance hole is incorporated in BX gaskets which ensures the pressure equalisation. Our range includes BX150 to BX303 gaskets for various applications.

SRX Gaskets

The "S" prefix in SRX indicates that these gaskets have intersecting vent hole these vent hole prevent pressure lock and enable any water trapped between the ring groove and the sealing area to escape. SRX gaskets match RX gasket measurements and excel in demanding subsea applications.

SBX Gaskets

SBX gaskets are vital for high-pressure sealing in challenging industrial settings. They resemble Type BX Ring Type Joint gaskets but feature intersecting vent holes (prefixed with "S") for pressure-less metal-to-metal contact, meeting according to ASME B16.20 and API Stdandard 6a standards.

SBX Gaskets

SBX gaskets are vital for high-pressure sealing in challenging industrial settings. They resemble Type BX Ring Type Joint gaskets but feature intersecting vent holes (prefixed with "S") for pressure-less metal-to-metal contact, meeting according to ASME B16.20 and API Stdandard 6a standards.

VX-AX Gaskets

VX gaskets excel in tough conditions, vital in oil and gas for wellheads and riser connectors. Face-to-face pressure design ensures secure sealing. AX gaskets prevent galvanic corrosion and offer electrical resistance.

VX-AX Gaskets

VX gaskets excel in tough conditions, vital in oil and gas for wellheads and riser connectors. Face-to-face pressure design ensures secure sealing. AX gaskets prevent galvanic corrosion and offer electrical resistance.

IX Gaskets

IX gaskets (IX 15 to IX 1200) adhere to NORSOK L005 standards, using NORSOK M650/M630 materials with PTFE/XYLON coating and color coding for material identification. Custom options, including silver coating, are available.

Delta Gaskets

Lens Ring Gaskets

Bridgeman Gaskets

RTJ Blind Gaskets

Seat Ring

Bonet Ring Gaskets

Protective Coating

As per specifications in API standard, soft iron and low carbon steel Ring Type Joints are electroplated with zinc to a maximum thickness of 13μm. Tyco Sealing has capability to electroplate Zinc, Nickel and Silver coating